[ad_1]

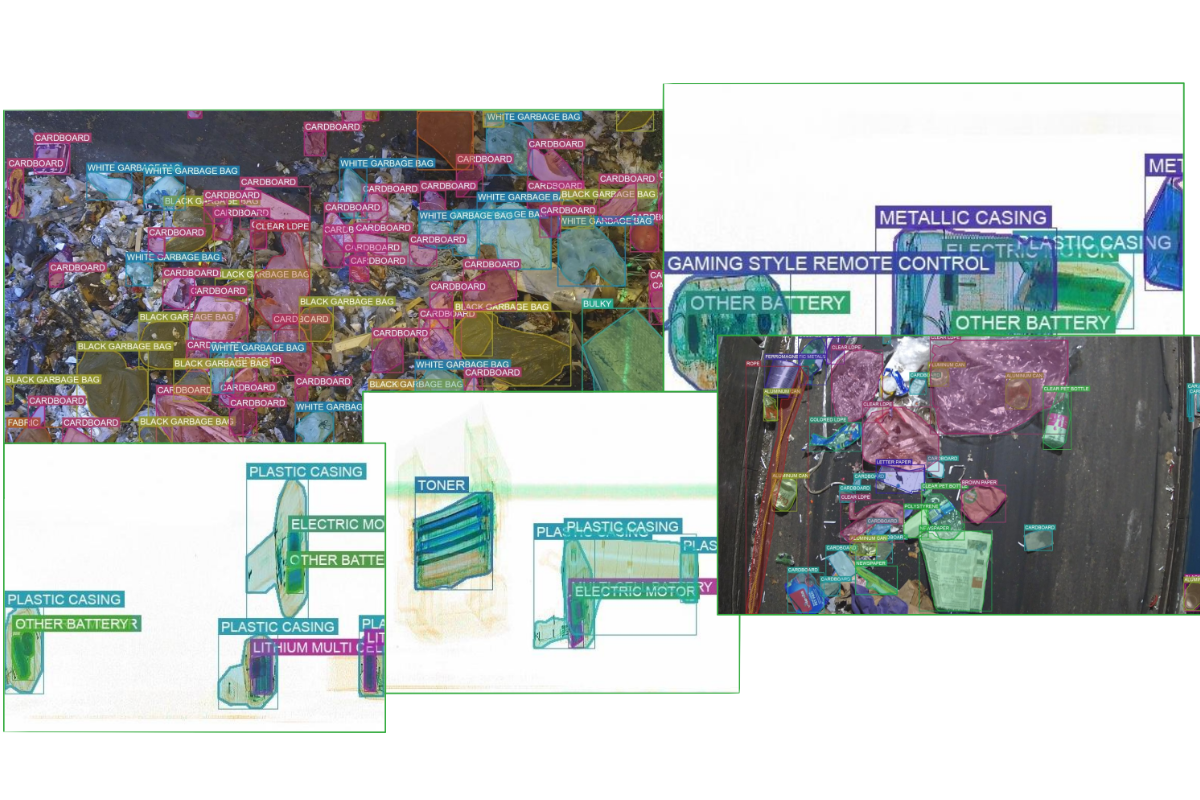

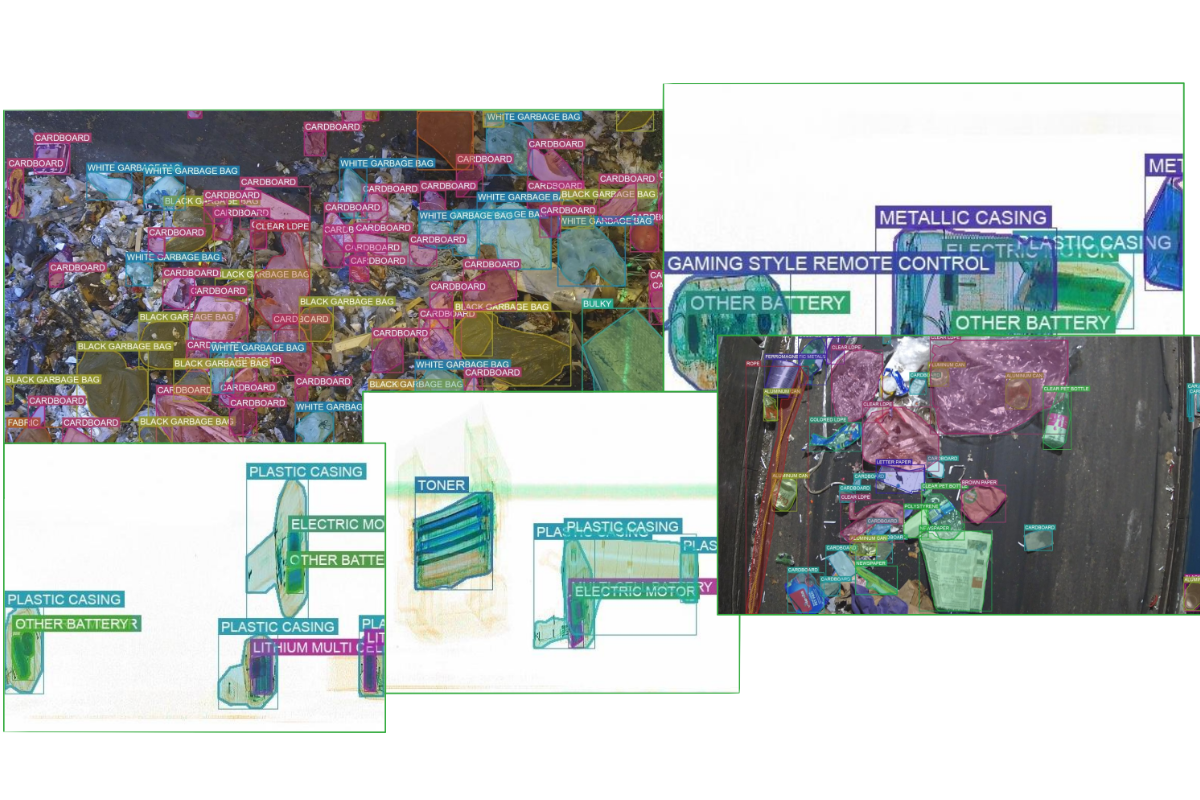

BinIt’s Visia system combines cameras, X-rays, and artificial intelligence to find batteries hidden beneath or within streams of recyclable materials. | Provided by BinIT

A young technology company’s imaging system combines cameras, X-rays and artificial intelligence to help recycling facility operators peer into waste streams and eliminate hidden threats from lithium-ion batteries and other hazards. , the company’s CEO said in a recent interview.

This idea seems to be catching on. BinIt’s system is in operation or planned to be installed at more than a dozen facilities, and the company announced Monday that it has been accepted. $6.4 million in seed financing We are receiving input from multiple investors to continue meeting the needs of our existing customers and expand to more facilities.

CEO Raghav Mecheri said the technology is a solution to the biggest problems facing the recycling industry today.

“No matter what you are or what kind of facility you run, at the end of the day these are big fire hazards,” he told Resource Recycling last week, referring to batteries and similar items. he said while doing so. “Being on the front lines of stopping battery fires in MRFs is probably what excites us most.”

“True material visibility”

Thousands of fires occur at recycling facilities each year, and rechargeable batteries are one of the main causes. recent reports From the National Waste Recycling Association. MRFs of all types frequently crush and pack cardboard and other materials that easily hide workers and non-directional devices such as automated sorting machines, completely eliminating battery hazards. It’s becoming a storm.

BinIt gets around this problem by reaching beyond the visible spectrum of light. Similar to airport baggage scanners, the system, named Visia, uses X-rays to see through textiles, plastics, and even some metals to identify the unique characteristics of batteries, sharps, and other items. Can be identified. It then alerts facility personnel using an app or a laser that spotlights problematic items on the conveyor.

Mecheri said the system has a capture rate of over 95% and continues to learn with experience from all locations. When facility managers combine her BinIt’s visible light with her X-ray capabilities, they get a complete picture of what flows into their buildings.

“We describe ourselves as the first true materials visualization business,” he said. “This is proving to be a game-changer for our customers.”

Those customers include evTerra, an electronic scrapping company with locations in Atlanta, Chicago and Las Vegas. Jeff Gloyd, then president of evTerra, spoke about the partnership with BinIt at last year’s E-Scrap conference. During September. He resigned from his position at evTerra in October and earlier this month he joined the BinIt team.

Unlike municipal recycling facilities, e-scrap facilities may want to store batteries and other hazardous materials that may be thrown into the stream, but they also want to separate them before sparks or flames erupt. He pointed out that

“It’s batteries, it’s propane tanks, which somehow always ends up in the waste stream, and it’s toner cartridges,” Gloyd told the conference audience. He added that the search and deletion process is typically manual, time-consuming and prone to routine human error, and BinIt offers a better option.

“When you factor in the downtime, the risks, the potential injuries to employees, etc., the ROI is pretty short,” Gloyd said in September.

Initiatives for growth

BinIt’s roots trace back to Columbia University in New York City. So Mecheri and several of his partners first started working on developing his AI assistance system. waste separation system Mesheri will graduate in 2022. His first-year roommate, James Bollas, is BinIt’s co-founder and chief technology officer.

Mescheri said the team came to see recycling as one of the most important areas, and after graduating, they visited every MRF they could, doing odd jobs like fixing internet connections while also learning about the industry and its problems. It was helpful while observing.

The Visia system was launched in January 2023 and initially used only visible light cameras. But facility managers have repeatedly asked for a way to see through piles of materials. Witnessing the battery fire firsthand was “shocking for us,” Mescheri said.

In the short term, Mescheri hopes to grow the number of customers from a dozen to at least 30 by the end of the year. Additionally, he wants facility managers to understand the system’s potential beyond just batteries. With a complete and detailed view of the material flow, “there is tremendous scope to optimize operational decisions,” he says.

More stories about challenging materials

[ad_2]

Source link